audusa

Main menu:

Why Cryo

The first commercial application of cryogenics to an audio component can be dated back more than 40 years. In the 40 years that have passed very little research has been conducted on the benefits of Deep Cryogenic Treatment (DCT) to audio cables and components. Many companies have cropped up in this time offering a DCT service for any one that wishes to have their cables or components treated. Unfortunately most of these companies do not have chambers and rely on a third party for processing. All to often the third party is more than willing to process audio components along with tool steels, engine components etc. to reduce cost and increase bottom line. At Frozen Solid Audio we consider this bad practice for a couple of reasons:

1) Nitrogen acts a dispersing agent, during a typical processing cycle the lubrication that is normally on these materials (tools & engine parts) is for the most part dispersed throughout the chamber and eventually vacated from the chamber. However not all the lubricant is vacated and eventually can settle on cable and components. Petroleum based lubricants that are allowed to make contact with audio grade silicone / polymers can cause the material to perish pre-maturely.

2) Often cited and still used is the 3 stage processing technique; i.e. slow cool down – long soak - slow return to ambient. This technique is great if you are trying to precipitate carbides in tool steel and yes it yielded good results sonically. However one of the side effects of this technique was the increase in micro-hardness levels.

* Increasing hardness levels actually promotes micro cracking and increases stress in the conductor

* Micro cracking promotes oxidation and exfoliation type corrosion

At Frozen Solid Audio / Frozen Solid our staff consist of personnel that have been working in this field for more than 10 years. We are confident in proclaiming that our breadth of knowledge is unsurpassed in the field of DCT of audio components. At Frozen Solid Audio we have developed our own proprietary processing technique based on empirical findings. We call it "Crystal Sound Technology™". What follows is a little taster of Frozen Solid Audio’s treatment "Crystal Sound Technology™" as compared to the more conventional DCT techniques employed by other companies.

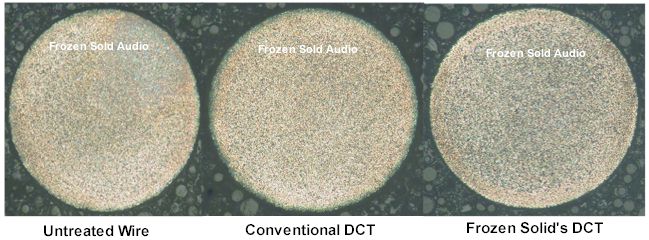

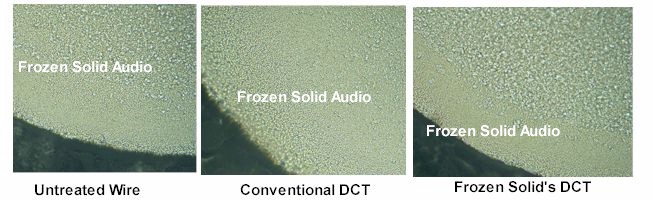

In each of the scanning electron microscope pictures a really noticeable difference is evident in the surface layers of the Silver conductor. This effect at high magnification is of a refocusing of the outermost skin of the post process conductors, the surface is more closely packed and regular, and has a continuity which aids conduction through removal of voids left by the drawing process.

That a continual conductor offers lower resistance than one with mechanical discontinuity is pretty much inarguable. Electron flow through an air gap is far less easy than through the best electrical conductor on the planet!

Drawing Silver or Copper develops a distorted ‘grain’ structure and leads to tiny voids, disruptions and discontinuities in the conductor as the metal is compressed and contorted by the drawing process. OCC conductors were implemented specifically to reduce this effect, the reasoning being that signal can be adversely affected by traversing multiple irregularly formed grains; the grain boundary can act as a tiny circuit, with capacitance, inductance, and a diode effect. This theory also lends itself to the notion of directional cable, whereby signal passes more effectively in one direction than the other. We certainly agree that consistency of grain is a good thing, but have also had great success in treating our customers continuous cast material to improve its sound!

Average Microhardness Levels Transverse sections

72.5HV0.1 76.1HV0.1 <70.0HV0.1

Average Microhardness Levels Surface sections

72.9HV0.1 76.7HV0.1 <70.6HV0.1

Frozen Solid Audio’s DCT applied wires are consistently measured as being less hard than the original wire, In fact 3.5% less hard. The standard DCT treatment wire is 5% harder, and this accounts for the ‘brittle, cracked and crazed’ horror stories which we hear when the ill advised seek to use DCT techniques only suitable for industrial tool steels. Our quality proprietary DCT processing leads to the development of a more refined crystal structure and removal of stress induced work hardening from manufacture. Your materials are then able to offer you their best performance.

On The Surface

The Bear Pit

There is much discussion within the audio world as to the audible influences of ‘skin effect’. This term describes the phenomenon of AC frequencies tending to flow around the outer surface of a conductor, there is no dispute on this subject, it happens, it’s a fact. What is also pretty evident is that this phenomenon occurs in frequencies beyond the audible range. So where does the enhanced surface condition of our DCT wire come in to all this? Firstly we feel that there is more to be known about electrical signal and its audible effects than is known today. That’s not a fudge, after all we have been told for years that the human ear cannot discern frequencies above 20kHz, and yet fortunes are being spent on loudspeakers which offer up to 100kHz response, and they work! Equally we all take note of a cables ability to reject interference, or deal with it effectively, and it is those very RF frequencies which a Cryo-treated cable is able to transfer more effectively.

There will be many that argue these last points, we don’t have time to argue, instead we’re working with audio manufacturers and experts to prove what it is we are achieving. Our mission is to prove what we have heard, and to help the audiophile realise that treasured musical experience in the comfort of their own home.

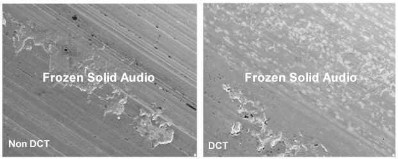

Non-DCT (Left) electron image shows the surface of our Silver wire pre process. Despite its surface being of the highest industry standard, there are a number of deformities evident. The long lines running diagonally show the gouging of the surface as it was pulled through the die which formed its shape and diameter; under great strain these lines are formed as the die indents itself. Compressing the metal in an inconsistent manner over its surface and building stress in to the material. Also present on this scan are small dark voids in the surface and larger crater type markings which indicate the die was ‘grabbing’ at the materials surface, in doing so removing metal and replacing it at random along the wire length.

Frozen Solid Audio’s DCT (Right) scan shows the final DCT processed wire. Again our proprietary process has effected an enormous and unique change over the two previous scans. Surface striation is all but removed by the thermo-mechanical effect of Frozen Solid Audio’s DCT processing technique. This would be all but impossible to achieve using any other engineering technique. Although material lost in the drawing process cannot be replaced by DCT treatment, the craters left are less deep as the underlying grain structure has regained its original dimensions. Interestingly, and beneficially the voids shown in the first view are reduced drastically in number and size, providing greater continuity of the conductor surface.

Just some of the benefits of using Frozen Solids DCT over the so-called competition:

* Structural continuity

* Reduction in compressed grains, more consistent grain size, less directional, less requirement for ‘burn in’

* Reduction in stress in the material, less susceptible to work hardening, longer service life with increased detail and transparency.

* Smoother surface for reduced skin effect for high frequency signals.

* More regular distribution of grain size, overall increase in grain size hence less grain boundaries to interrupt signal flow.

* Increased musical detail, clarity and transparency.